Product Design

How to design with carbon fiber or fiberglass

Designing products with carbon fiber and fiberglass opens up a world of possibilities, whether you’re designing a product from scratch or converting an existing part from metal or plastic. Here are a few items to consider during this process:

Essential Factors

Definining the Benefits: Before beginning the design process, it’s essential to identify the specific benefits you want from composites. Whether you aim for weight reduction, increased durability, or unique material properties, clarifying your objectives will guide your entire journey.

Understanding Product Usage: Knowing how your product will be used is fundamental to effective design. You will need to consider mechanical and structural requirments, having an idea of the weights, forces, loads, or pressures your product will see. Identify the temperature range your product will need to withstand, as well as other environmental conditions such as moisture, chemicals, and UV exposure.

Integration with Surroundings: Understanding how your composite component will fit into a larger assembly is crucial. Consider the ease of installation and alignment, and plan how it will interact with other components. Decide whether to use bonded attachment points or fasteners. Ensure adequate clearance is factored in for proper assembly and function.

Cost Considerations: Understand your market and business costs. Research similar products and determine a competitive target cost range. This helps guide decision-making during the design phase, balancing quality and affordability.

Additional Design Factors

Industry Standards and Compliance: Identify any industry-specific standards or regulations your product must meet. This ensures compliance and functionality, preventing costly modifications later.

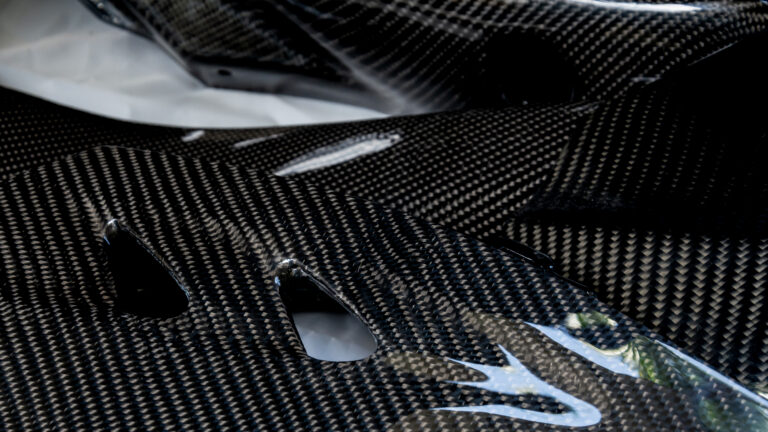

Design Aesthetics: Consider the visual and tactile aspects of your product. Decide whether to showcase the fiber itself, or apply paint or wraps. If showing the fiber, choose from various weaves or options like forged or burn-through patterns. Dyed fibers or pigmented resin can be used to achieve desired colors. Determine if the surface should be smooth on one or both sides, or if a rougher texture is needed or permissible in certain areas.

Durability: Define the expected lifespan of your product. Ensure the design is durable enough for its intended use. Consider maintenance or repair needs, providing easy access where necessary.

Design for Manufacturability: Create designs that are practical for cost-efficient production. Understand common manufacturing processes and ensure that features are feasible. Avoid design that, while optimized for performance, are difficult or expensive to produce.

Sustainability and Lifecycle Management: Incorporate sustainability into your design process. Consider the entire lifecycle of the product, from material sourcing to end-of-life disposal. Designing with sustainability in mind not only benefits the environment but can also reduce costs and enhance product appeal.

By carefully considering these factors, Laminate Engineering helps you design carbon fiber and fiberglass products that are innovative, functional, and market-ready. Reach out to us to start your design journey today.

© 2024 Laminate Engineering, LLC

All Rights Reserved.